2-cycle Gimsamotor®

The 2-cycle Gimsamotor® (2-ZGM) can be used for a variety of applications. It can be used, for example, in combined heat and power units (CHP) for heat and power supply in buildings, but also for boat drives or for seawater desalination, where not only electricity but also heat is generated to evaporate salt water. The water vapour precipitates as condensate and the seawater has been separated from the salt by this process.

Unlike petrol or diesel engines, where explosive internal combustion takes place, the heat transfer in Stirling engines is external. This means that any heat source can be used. However, temperatures of around 1,000 °C must be present to heat the Stirlingheater.

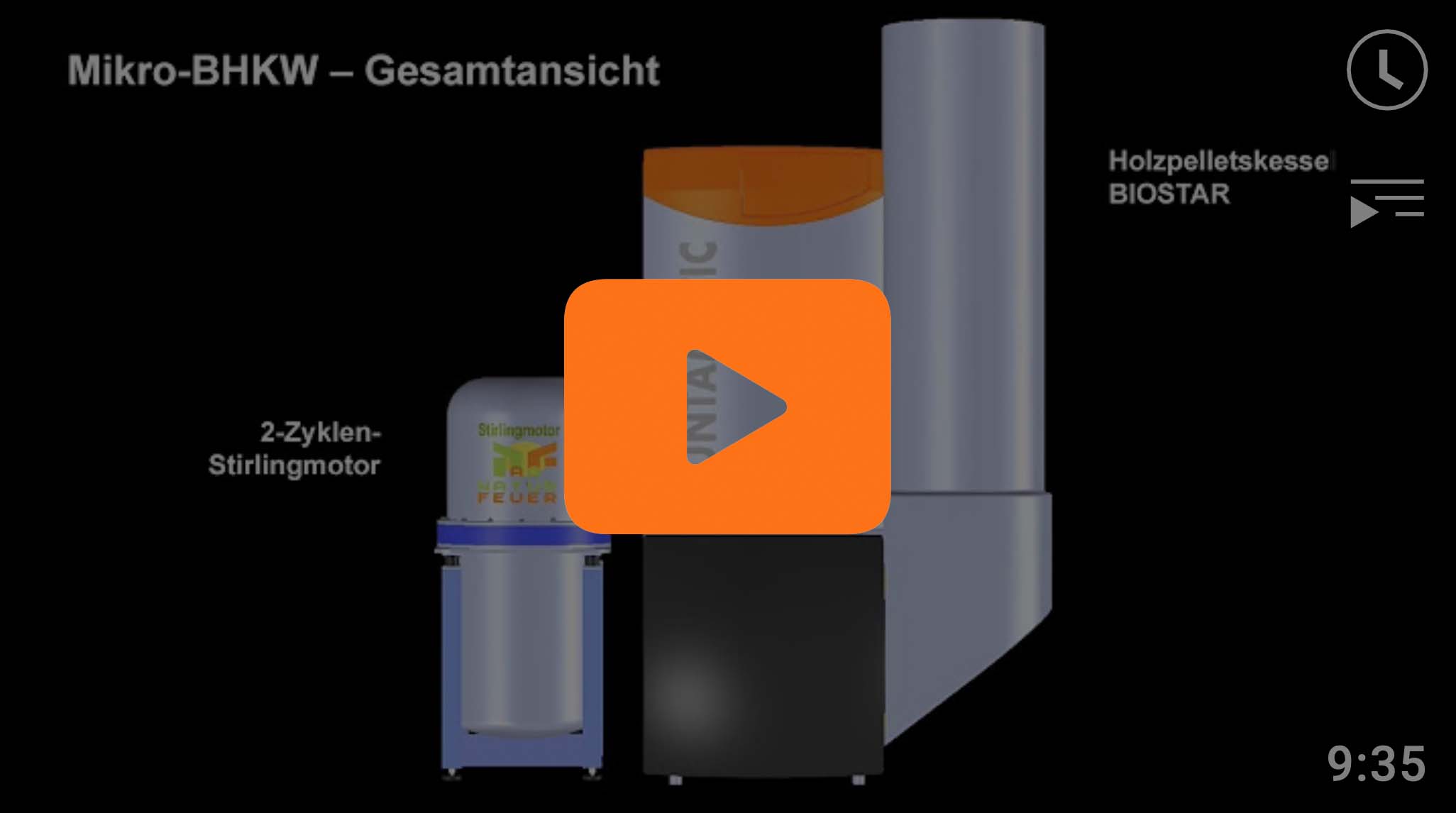

Micro-CHP with 2-cycle Gimsamotor® and wood pellet firing

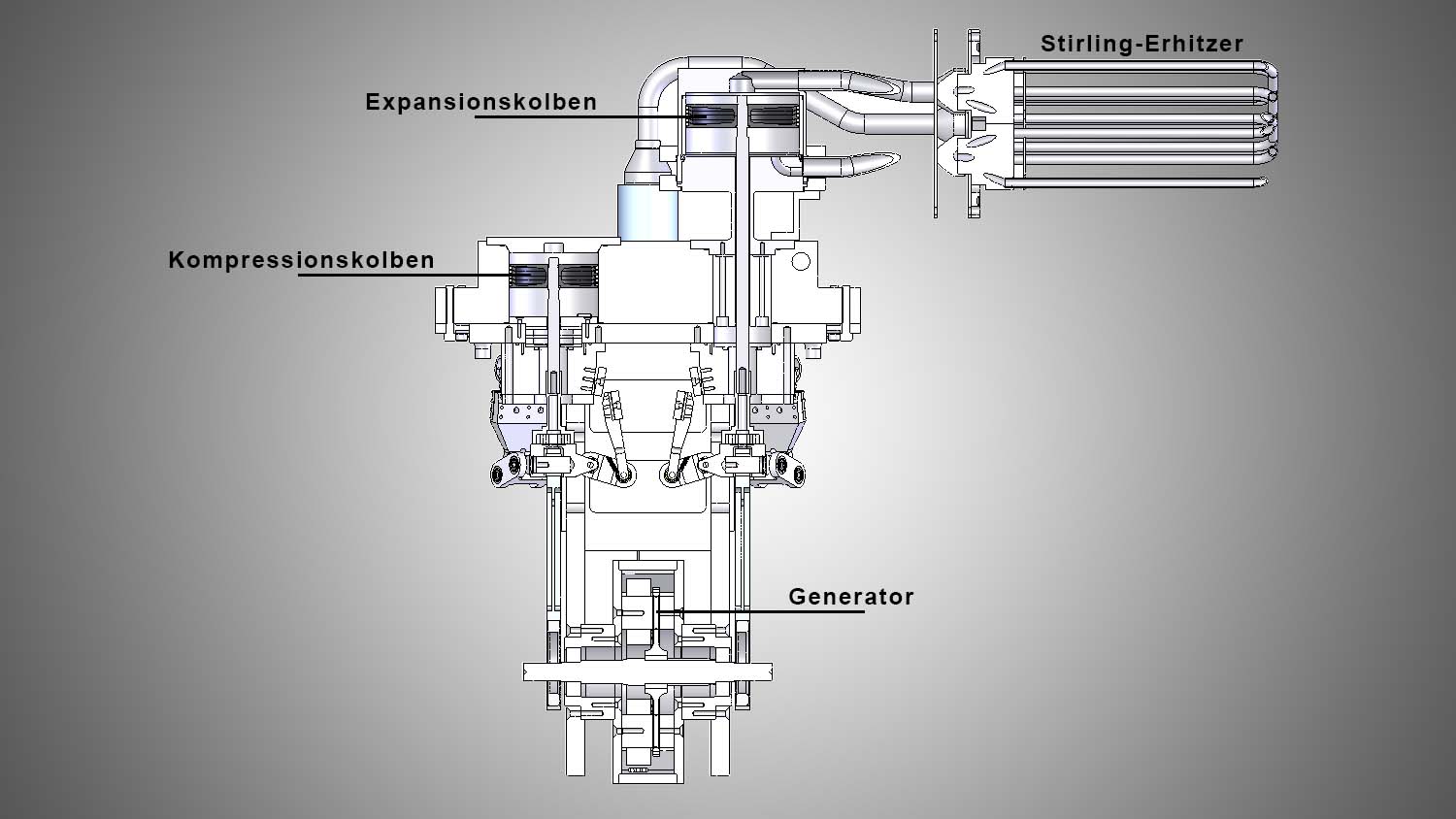

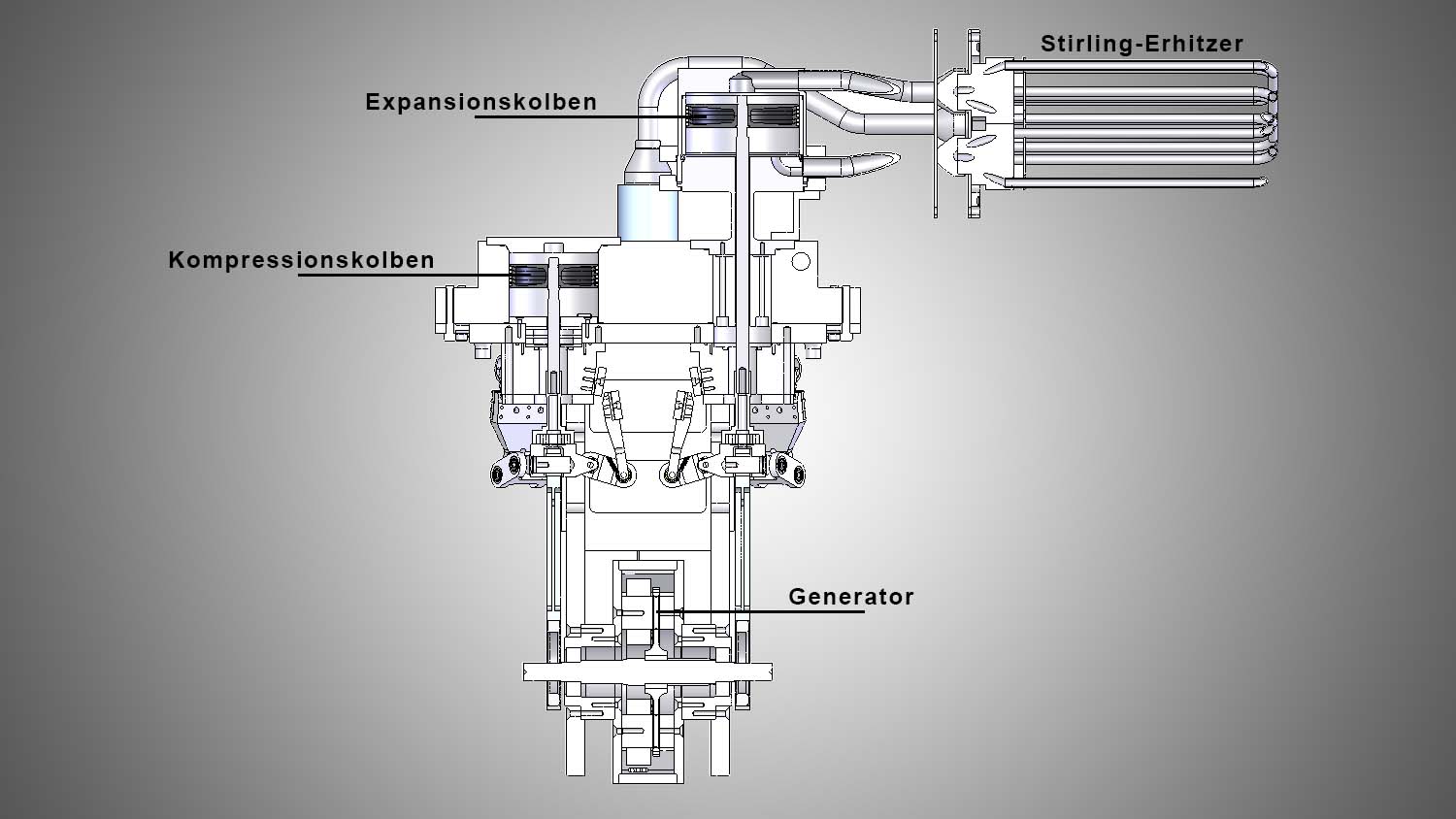

The Stirling engine is an alpha type with two Stirling cycles operating with a phase shift of 180°, with one piston acting as the expansion piston for both cycles and the other piston acting as the compression piston for both cycles. The expansion pistons are heated by the heater, while the compression pistons are cooled by the cooler.

Cut from the 2-cycle Gimsamotor®

View of the 2-cycle Gimsamotor® with pellet boiler

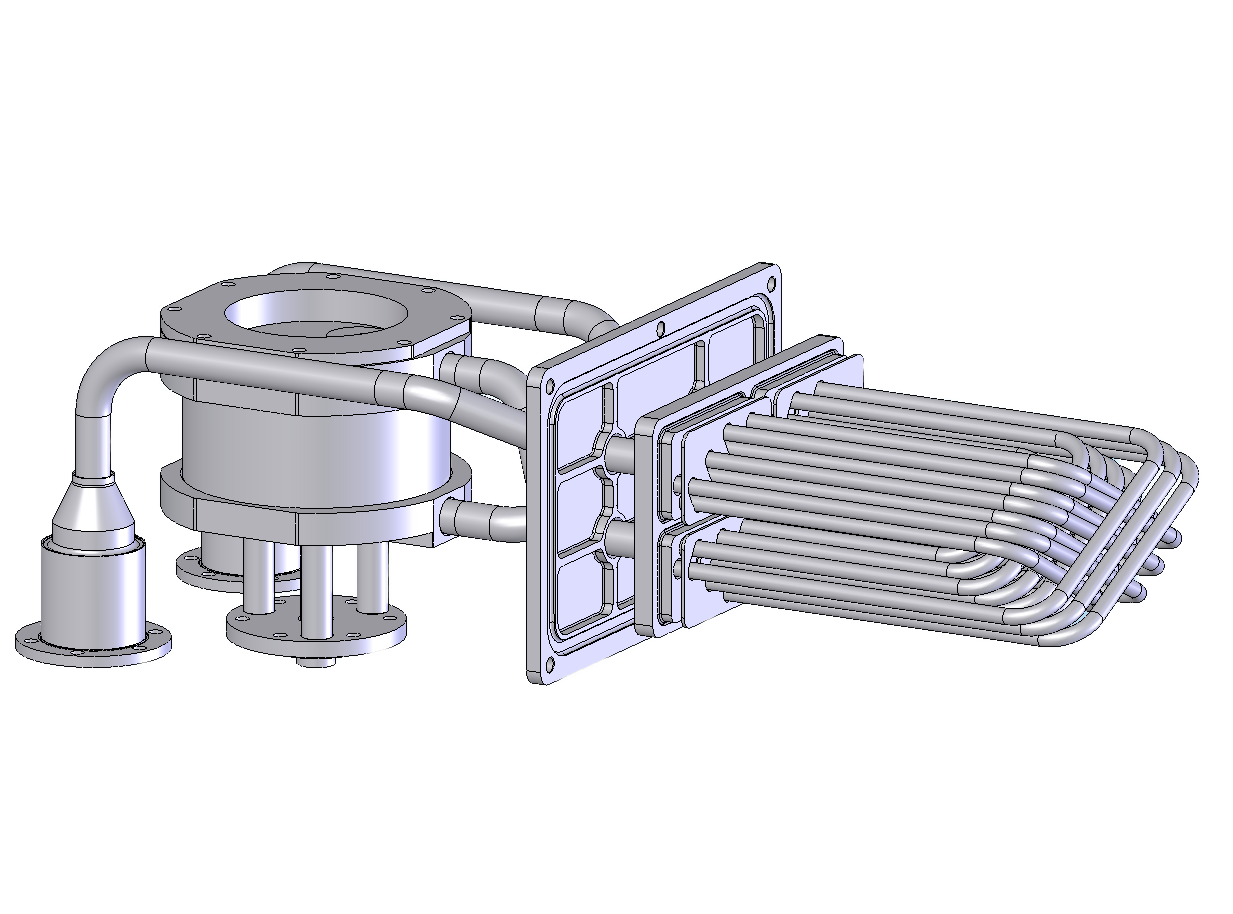

The heating unit of the 2-cycle Gimsamotor® projects laterally into the patented cyclone combustion chamber of the pellet boiler. The low-wear cyclone combustion chamber has a very high degree of ash separation, which prevents or minimises the formation of slag on the heating pipes.

The engine can convert its Stirling process using the heat given off by the pellet boiler. The generator turns and produces electricity with an electrical output of approx. 1 kW. The system is cooled via the return flow from the heating system. It emits heat at a low temperature level with a thermal output of approx. 3 kW.

The heat given off at a low temperature level can either be fed directly into the buffer storage tank or into the house via a separate heating circuit, e.g. for underfloor heating.

With a heat output of approx. 10 kW, the pellet boiler covers the peak load and supplies the heat required for the building at a high temperature level.

The lateral arrangement of the Stirling engine has the advantage that the pellet boiler can also be operated without the Stirling engine. In this case, the opening in the combustion chamber is closed with a flange.

General:

- Fully automatic operation

- Overall efficiency of 91 % (N), 92 % (He)

- Electrical efficiency of 23 % (N), 31 % (He)

- Undercutting of the emission limits of the 2nd stage of the 1st BImSchV

2-cycle Gimsamotor® (2-ZGM):

BIOSTAR COMPLETE pellet boiler (GUNTAMATIC):

Micro-CHP with 2-cycle Gimsamotor® based on wood pellets

Animation with our new 2-cycle engine

(redirection to YouTube)

HT storage system - Ericsson battery (planned values)*:

- Storage medium: NaCl

- Storage mass, filled: 2,000 kg

- Storage volume, uninsulated: 1 m³

- Maximum temperature: 950 °C

- Storage capacity: 565 kWh

- Expected service life: > 100,000 charging cycles

* Research project funded by the Federal Ministry for Economic Affairs

and Climate Protection based on a resolution of the German Bundestag.

Funding reference number: EP201356