Company

NATURFEUER AG produces, distributes and installs environmentally friendly decentralised energy systems. One focus of our work is the manufacture of innovative Stirling engines, which we produce at our company site in Potsdam. Special double-acting Stirling engines that work with hot expansion cylinders are the focus of our work. Production was preceded by many years of development work.

Energy saving and environmental protection

Our convern is to leave an environment worth living in for future generations. “Energy saving and environmental protectionˮ play an important role in this. Against the backdrop of finite fossil resources, we are faced with the task of making our energy supply more efficient and environmentally friendly. Energy from sustainably produced CO2-neutral biomass is an important component of this. This form of energy conserves fossil resources, makes an important contribution to climate protection, makes our economy independent and creates jobs and prosperity in the country.

What makes Stirling engines so attractive?

A major advantage of Stirling engines is that they can utilise a variety of different heat sources for the drive. This is because the heat is supplied to the engines from outside. This results in a high degree of flexibility in the choice of heat source. In addition to conventional energy sources, CO2-neutral fuels such as biomass, biogas, vegetable oil or bioethanol can also be used. Solar systems or energy storage systems can also be used. As there is no explosive combustion in the engine, the engines are extremely quiet and generate only minimal vibrations.

Naturfeuer-Stirling engines have potentially higher thermal efficiencies compared to conventional Stirling engines, especially at constant temperatures. Due to the low mechanical load and few moving parts, Stirling engines are generally durable and require less maintenance than conventional combustion engines. Stirling engines have no spark plugs, valves or filters that pollute the environment. They are low-wear and run completely oil-free.

Micro-CHP with Stirling engine and biomass boiler

One way of combining a Stirling engine with an external heat source would be to use it in a biomass boiler with wood pellet operation. The biomass boiler supplies the peak load required for the building.

The innovative 2-cycle Gimsamotor® (2-ZGM) with an electrical output of approx. 1 kW and a thermal output of approx. 3 kW has already been successfully tested in this configuration at the Potsdam site. NATURFEUER AG has now started production of the first small series.

Wood pellets are particularly suitable as a solid fuel for Stirling engines, as they can be burned continuously in a modern wood pellet boiler and have a comparatively high combustion quality.

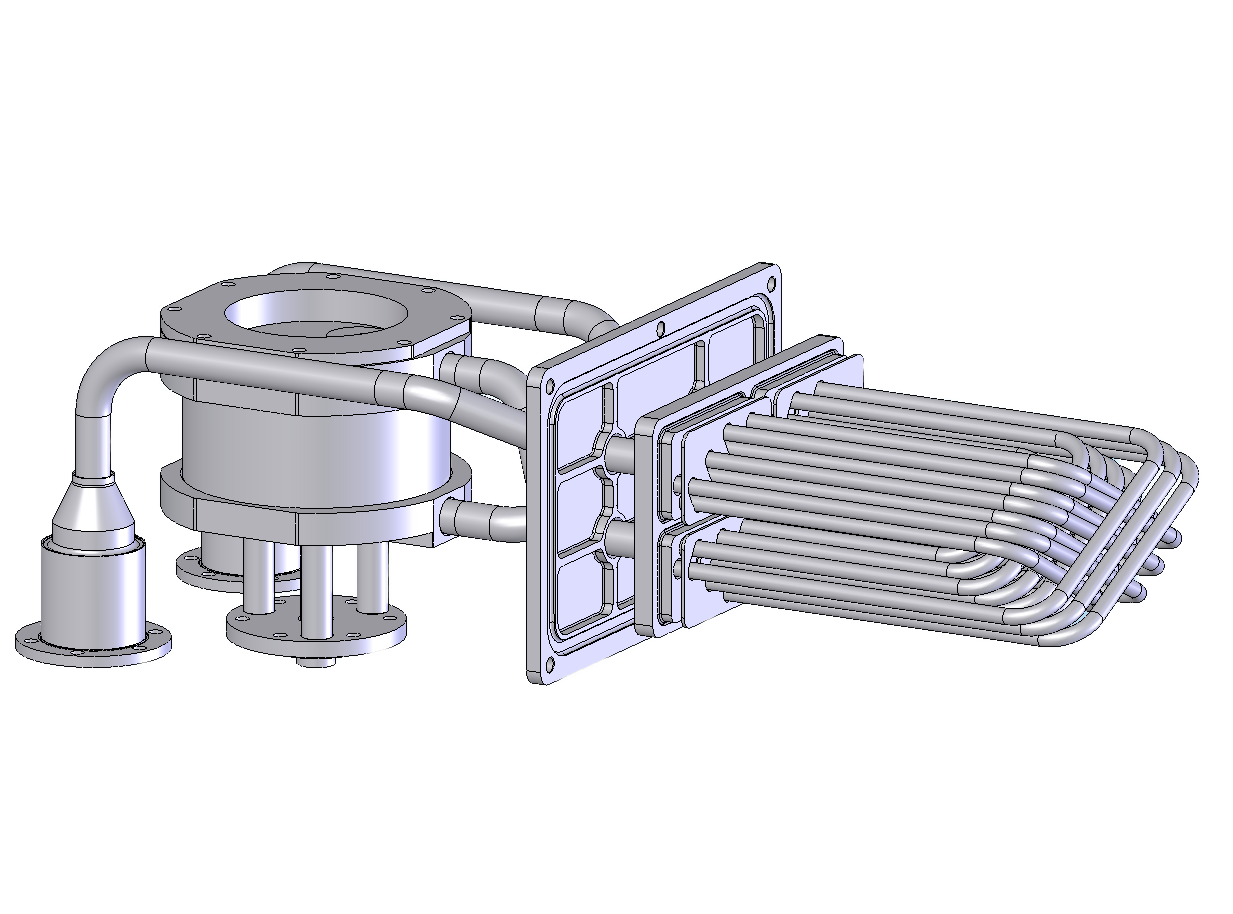

Ericsson battery

In addition to a well-insulated high-temperature storage unit, the Ericsson battery contains an improved Stirling engine that does not require a lithium-ion battery and can absorb and release electricity at any time.

This configuration therefore combines a Stirling engine with a high-temperature storage system. Such a storage system, known as an "Ericsson battery", is currently being developed by the company ENERLYT Technik GmbH from Potsdam. Heat is supplied to the storage system using electric heating cartridges.

When there is an oversupply of electricity, especially when the sun is shining and the wind is strong, the battery is charged using the heating cartridges. If there is a shortage of electricity, the storage system is discharged again. During the discharging process, the previously stored energy is converted back into electricity and heat via the Stirling engine. This micro CHP unit has an electrical output of approx. 3 kW and a thermal output of 6 kW. The low-temperature heat generated is up to 100 °C and is therefore very suitable for existing houses and heating networks.

Future potential

We see ecological and economic future potential in the decentralised generation of electricity and heat with the help of a combined heat and power plant operated with biomass or a high-temperature storage system.

Fossil fuels such as natural gas or heating oil will be difficult to calculate in the future. In addition, the CO2 levy introduced from 2021 will make heating with natural gas and heating oil significantly more expensive.

Heating with renewable energies is more environmentally friendly. Wood is a popular energy source and an easy way to reduce CO2 emissions in buildings. Changing the heating system often pays for itself quickly thanks to lower fuel costs and attractive subsidy programmes. The principle of combined heat and power generation also means that power plant capacities can be saved.

The inclusion of energy storage systems is also essential in order to achieve continuous supply stability. Overall, energy storage systems, such as the Ericsson battery, contribute significantly to the flexibility, efficiency and reliability of modern energy systems and are essential for the successful integration of renewable energies.