Manufacturing

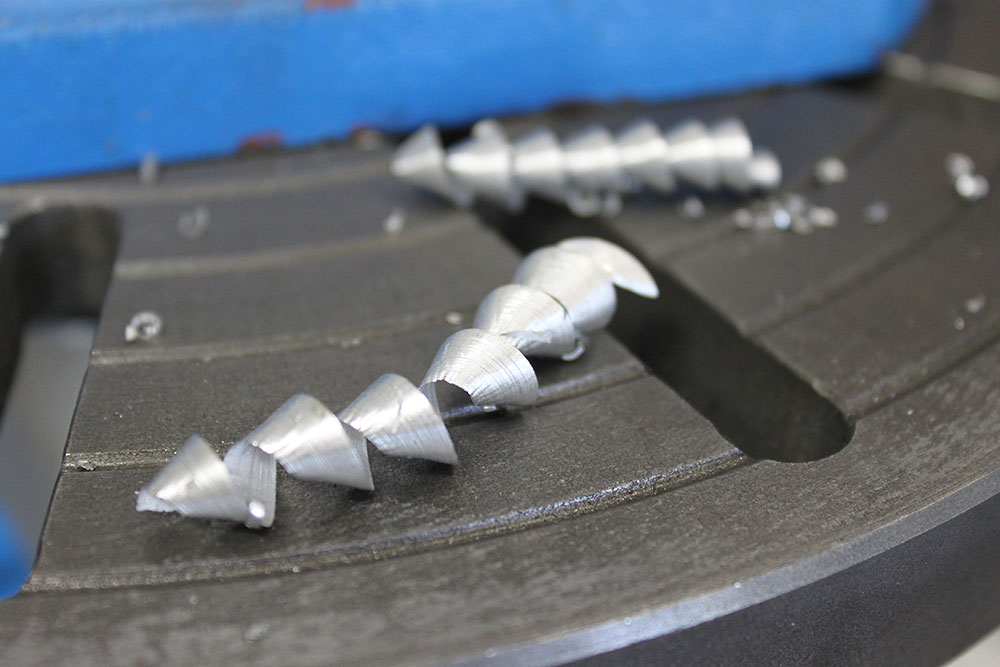

We manufacture almost all components of our various Stirling engine designs ourselves. Various processing machines are used, such as our CNC machining centre or our lathe. The precision measuring technology used enables a very accurate TARGET-ACTUAL measurement of the manufactured components.

Ensuring quality

At NATURFEUER AG, special attention is paid to quality. No part is installed without rigorous testing. Our machines work with high precision with a measurement uncertainty of a few micrometres.

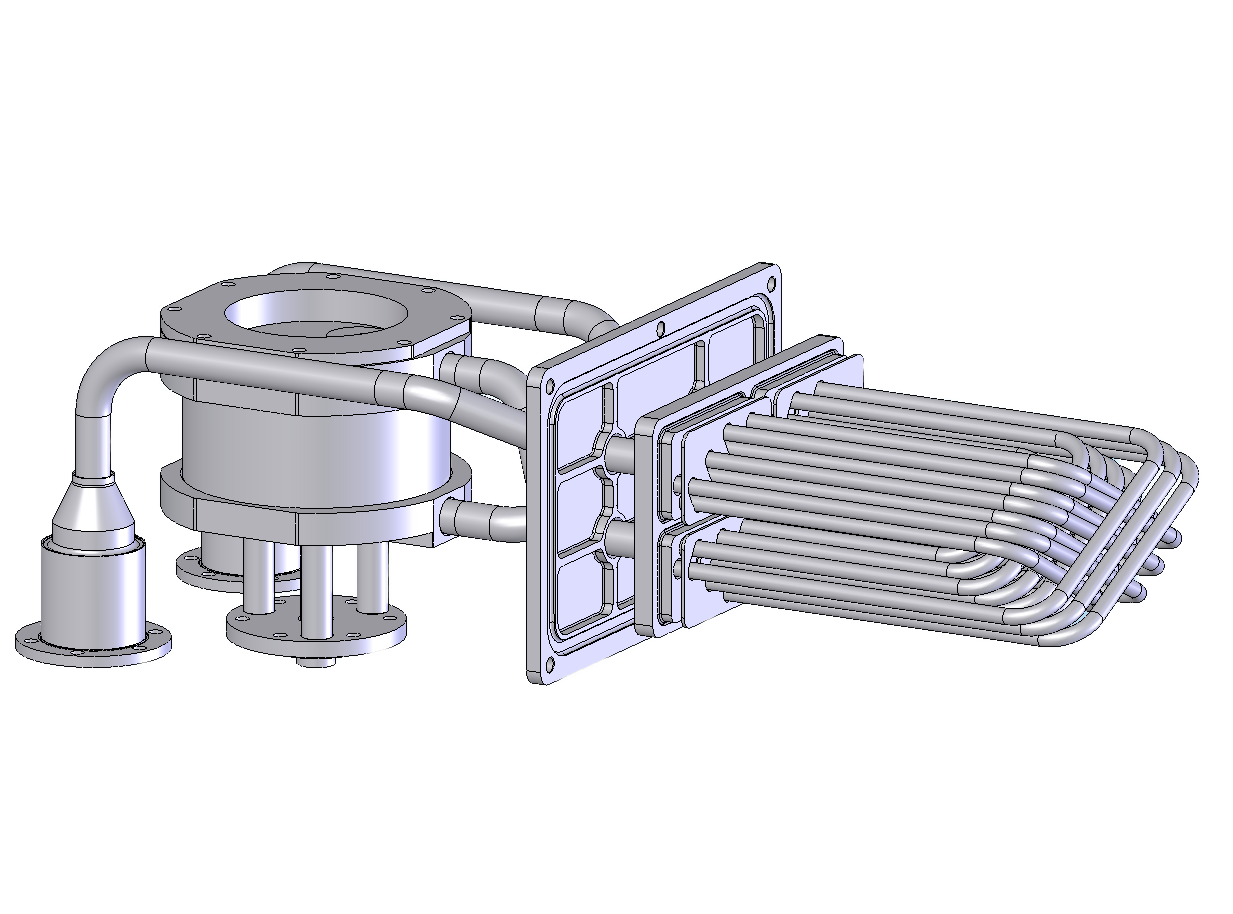

Professionally created programme data are the indispensable basis for successful process sequences in the CNC sector. Based on design plans created with Solid Works, the data stored there can be used to program the machine.

Assembly

Assembly is carried out by trained personnel using technical aids. This ensures the high quality standard. In the next few years, quality is the only yardstick at first, later quantity will also be the standard.

Test bench for Stirling engines

After careful inspection of the individual parts and subsequent assembly, the Stirling engines are tested on our test benches. This shows whether the engines meet the high requirements.

The following points, among others, are tested:

- Leak tightness

- Electrical power

- Thermal power

- Efficiency

- Noise level